Catch up with the state-of-the-art in ‘shift left’

‘Shift left’ is a well understood concept. The term was coined more than 20 years ago by software engineer Larry Smith and he summarized it simply enough: “Bugs are cheap when caught young.”

For semiconductor systems, the goal is to develop flows that allow designs to be reviewed and corrected throughout the process, largely because they can respond as a project evolves – from extra functionality to ECOs to IP addition and beyond. This improves design quality, ensures better verification on the way to sign-off, reduces iterations and shortens time-to-market.

A new White Paper from Siemens EDA looks at where ‘shift left’ stands today in the context of the Calibre physical verification platform. Calibre is a powerful enabler for early-stage analysis because it is the market leader among foundries and therefore infused with the manufacturing knowledge needed to achieve successful sign-off.

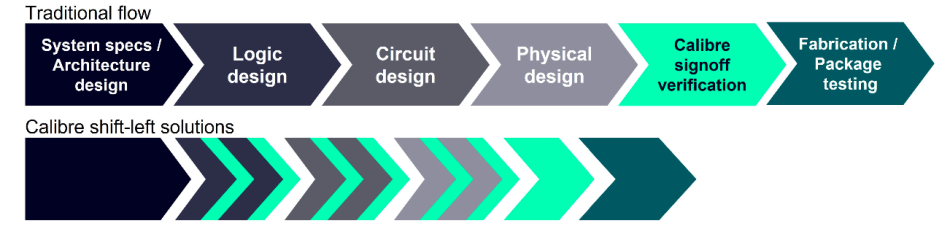

Author Michael White, Senior Director, Physical Verification Product Management for Calibre Design Solutions, describes how various parts of the Calibre family can now be used across a design flow, in comparison with a traditional approach that leaves the bulk of the physical verification task until late in a project. A broad comparison is shown in Figure 1, with the Calibre-inside benefits shown in green.

Figure 1. How Calibre is pollinating ‘shift left’ in the design flow (Siemens EDA – click to enlarge)

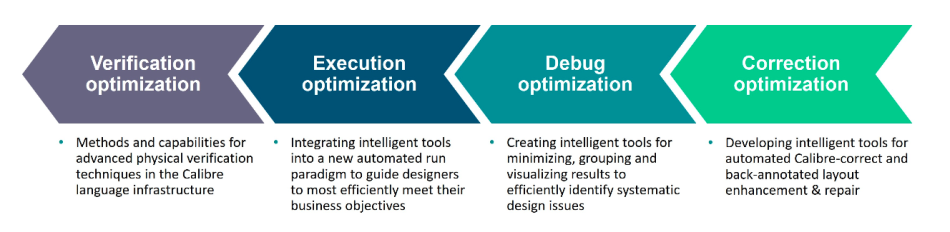

To pollinate a design flow with Calibre knowledge, White describes how Siemens’ approach is based on four ‘pillars’ (Figure 2) and cites the specific tools and functionality on which such a flow is built. This illustrates the current state-of-the-art in ‘shift left’ and highlights the continuous innovation needed to make sure such a strategy delivers on its promise.

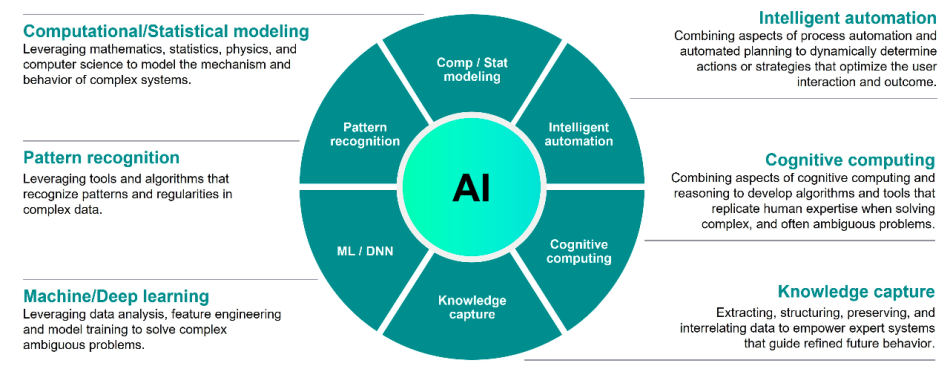

A key factor in the drive toward continuous improvement is artificial intelligence (Siemens has just launched Calibre Design Enhancer as its latest step along this road). White describes how leveraging AI is not limited to greater use of machine learning — currently the most widely discussed AI technique. A broad overview of his company’s approach is shown in Figure 3.

The job is not yet complete, but the paper provides strong evidence of how ‘shift left’ is already delivering greater efficiency and more accurate design and verification even as system design becomes more challenging.

‘Shift left with Calibre to optimize IC design flow productivity, design quality, and time to market’ is available for download here and is a valuable primer on how EDA is meeting a key customer requirement.