April 15, 2019

CAA is a valuable tool available to both design engineers and foundries to help them avoid layout-dependent effects during manufacturing.

May 22, 2012

Correlating production test failure diagnosis with DFM analysis can help identify and understand systematic yield issues, and to find out whether they are linked to DFM violations.

May 1, 2010

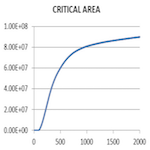

The time-dependent dielectric breakdown (TDDB) of inter-metal dielectrics on large-scale chips is becoming an increasingly important reliability issue across several semiconductor markets. This mechanism can cause early failures in use and is difficult to detect by traditional test, and hard to control by traditional reliability techniques.

May 1, 2010

The article offers a case study of the DFM planning and methodology applied during a shrink of Cambridge Silicon Radio's UF6000 system-on-chip from the 130nm to 65nm.

June 1, 2008

The paper describes some of the main challenges in the latest process shrink for the Cell Broadband Engine, developed jointly by IBM, Sony and Toshiba. The authors show how the move from a 65nm to a 45nm SOI process was achieved by concentrating on four primary goals: automating the migration; setting a 30% power reduction […]