Flexible hybrid electronics: Making an emerging tech happen with PDKs and reference designs

The flexible hybrid electronics (FHE) sector is now moving towards much greater maturity. A recently published technical article and accompanying video discuss the latest advances, notably the establishment of an overarching design process that has enabled the development of FHE PDKs and is delivering early reference designs along the path to modular implementation.

The article shows how this infrastructure is increasingly necessary as applications emerge in areas such as edge processing, health, automotive, military and soft robotics. FHEs can be created with the smaller form factors and lighter weight that make them useful as both sensing and processing systems for these use cases.

However, FHEs differ from traditional ICs in significant ways. Most obviously, different substrate and component materials allow them to flex and they require greater insight into the electromechanical requirements. Innovation is also needed to shorten their time-to-market.

The paper is written by Sean Nachnani, a hardware systems engineer with the NextFlex consortium. This is a public-private manufacturing-led vehicle, supported by US government agencies such as DARPA and NASA and companies such as Lockheed Martin, Boeing, Siemens Digital Industries Software and ON Semiconductor.

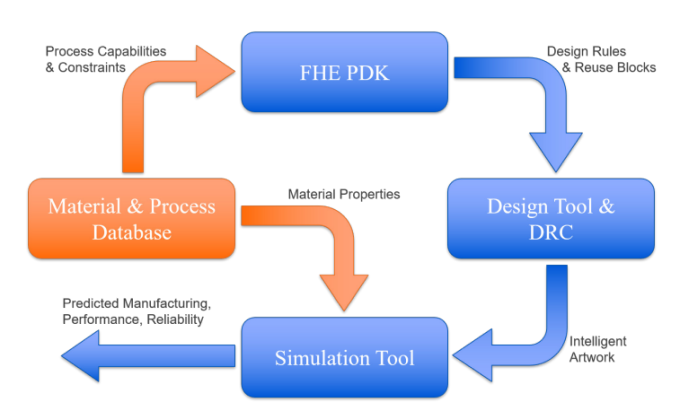

It sets out the FHE process (Figure 1) NextFlex has developed and how it has been built upon to enable FHE-based design and simulation around a dedicated PDK. “Ultimately, by following this design and process cycle, we come out with predictable manufacturing, predictable performance, and more reliable FHE devices,” writes Nachnani.

By way of example, the paper refers to the first two reference designs to emerge from the consortium.

One incorporates Bluetooth 5.0 based on technology from Nordic Semi integrated on the flexible substrate with an RGB LED and an external battery connection. “By starting with this reference design, you can just attach any additional sensors and any additional components that you bond to create your Bluetooth module in FHE design,” Nachnani explains.

The second is based on technology from On Semiconductor and incorporates sensors, an MCU and a Bluetooth antenna.

The paper also cites the use of the Hyperlynx software tools from Siemens for FHE-friendly design.

The reference designs are acknowledged to be early iterations of FHE design around the NextFlex PDK. “Going forward we plan to add in more and more of these modules to our library database, to this ecosystem,” Nachnani writes. “So ultimately, what we’ll end up with is an entire library of modules that allows us to truly plug-and-play. When we’re coming to a new design, we just pick the modules and that’s it, it’ll significantly reduce the time it takes to bring a device to the manufacturing step.”

The white paper can be downloaded here.

Nachnani also explains the concepts within it in this video.