Practical steps toward ECAD-MCAD integration for automotive design

Automotive engineers generally recognize the need for greater integration between the electrical and mechanical domains. Greater complexity can double design cycles and component costs. More seriously still, errors can lead to dangerous flaws making their way through to production vehicles.

The problem is well known, but how can companies achieve the necessary level of integration in practice?

A technical article from Siemens Digital Industries Software takes a deeper dive into ECAD-MCAD integration by examining how it works in the context of the company’s VeSys platform.

It describes examples of the crossovers where the two domains have particular influence on one another such as, for intance, how mechanical designers must be able to verify the physical space constraints of the harness according to the bundling thickness that is largely dictated by the wiring content.

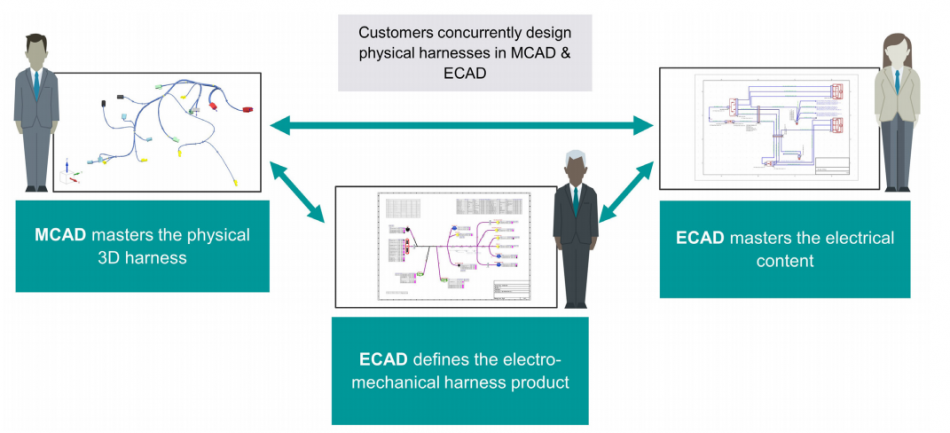

At the heart of the article is a detailed wire harness design example based on a flow that allows electrical and mechanical teams to work in their own domains but while fully informed of the context and work of their colleagues elsewhere as it progresses. An overview of the flow is shown in Figure 1.

Figure 1. Digitalization allows the electrical and mechanical domains to work closely together with greater insight (Siemens – click to enlarge)

The example shows how to benefit from the use of a framework of cross-domain bridges and adapters, and by leveraging a range of APIs to smooth the use of other popular automotive design software.

Integrated Electromechanical Wire Harness Design is available for download here.