The 10 ways to automate increasingly complex wire harness design

Just how far can automation go toward improving wire harness design in the face of increasing complexity, tight margins and largely manual processes? A white paper from Siemens Digital Industries Software seeks to address thaisquestion and proposes 10 areas where there opportunities for improvement.

The paper notes, “As harness complexity increases, these legacy methods will come under increasing strain, and eventually may fail completely.” You can arguably already seeing this happen in markets such as automotive. And all that is in addition to the risks long posed by late-stage change orders.

Siemens 10 proposed solutions fall into three categories. The full list is:

Reduce harness design cycle time and cost

- Automated harness engineering and validation

- Subassemblies to streamline production design

Improve product and process quality

- Controlled, automated change management

- Digital continuity design through production

Reduce harness manufacturing turnaround time and costs

- Full-scale formboard layout and fixtures

- Effective formboard utilization

- Factory modeling and bill-of-process generation

- Time and cost calculations to increase assembly process efficiency

- Balance tasks across a harness production line

- Ready-to-use work instructions for every stage of assembly

Each of these areas is considered within the context not only of available tools – Siemens itself offers the Capital software within its Xcelerator portfolio – and also increasingly common digital twin strategies that are spreading across many high technology design and supply chains.

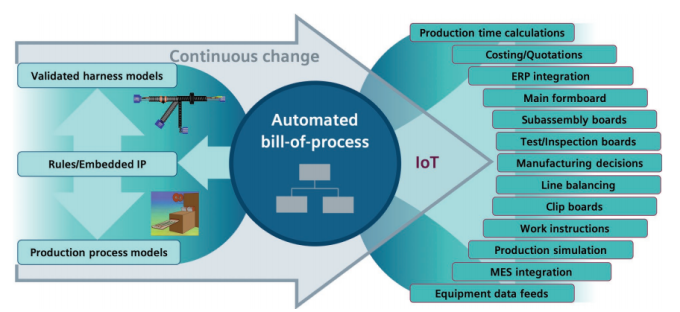

Figure 1. Digital continuity enables a high level of automation in the wire harness process (Siemens)

“An automated and integrated E/E system and wiring harness engineering solution, featuring robust data integrity throughout the development flow, will enhance the ability of manufacturers to produce advanced wiring harnesses on increasingly tight timelines,” the paper argues.

“This digital transformation is vital to grow revenues, increase profitability and ensure the future success of harness manufacturing businesses in an increasingly competitive environment.”

‘Ten ways to improve wire harness manufacturing‘ is available for download here.