Mastering automotive complexity through generative design

Generative design is a flow strategy that aims to help companies master three forces making automotive projects harder to realize: complexity, cost and change.

It applies rules-based automation so that designers can input a functional model of an electrical system that harmonizes its different parts (components, communications networks, power sources, etc) and specifications, and the generates architectural options for review, selection and optimization.

The three drivers are making this process to difficult to manage or control based on traditional human-led flows. Consider these data points:

- Adding just 20 optional features to an existing automotive system can increase the number of wire-harness configurations by roughly one million – and that is before any design takes into account further adaptations required to meet regional data points.

- A car capable of Level 2 autonomy is likely to contain 17 sensor systems to handle tasks such as cruise control, lane departure warning, lane keep assistance, and parking assistance. One that reaches full level 5 autonomy – where no human involvement is required – is likely to have at least 30, and the tasks they carry out will be more complex in nature and processing (e.g., stereo vision, dead reckoning).

In addition to complexity, this environment is also more prone to ‘domino’ or ‘cascade’ failures. Every change or addition made to an increasingly sophisticated system is likely to have some effect elsewhere (multiple power domains influencing wiring systems; component power and bandwidth requrements; themal envelopes; etc). But how do you track that?

Meanwhile, it is not just that design is becoming more complex and vulnerable to human error.

There automotive system market is seeing many new entrants. These companies are typically not that familiar with its design practices, safety assessment processes (e.g., ISO 26262 for functional safety) and its preferred re-use objectives (as high as 80% from one vehicle to generation to another).

At the same time, experienced automotive suppliers are finding themselves confronted by technologies that are unfamiliar and which are making greater calls on design resources.

Generative Design

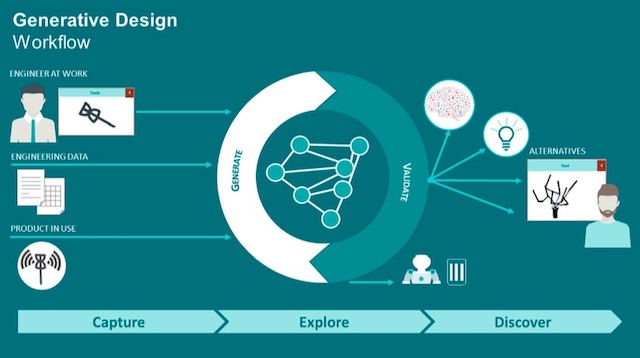

Generative design flows (Figure 1) are rules-based; they capture existing intellectual property (IP) and best practices. This gives newcomers easier access to the automotive market and frees up the resources of existing players to concentrate on new challenges and differentiation.

Once a functional model of an electrical and electronic system has been created (though without a detailed specification), the tools bring its various base elements together in a common format and output architectural proposals for the logic, software, hardware and network of the electrical and electronic systems.

Because all these different elements conform to a common format, changes made during optimization or to meet safety requirements will cascade through the whole project, and the results will be available to designers across its different disciplines.

Overall, this enables greater mastery over complexity, a more expansive way of controlling costs and a much clearer view of the benefits and deficits brought about by change.

Two interlinked technical papers from Mentor discuss the Generative Design concept and the associated flow in more detail:

- What is generative design and why do you need it?

- Generative Design for Autonomous Vehicle Electrical Systems

Both are available for immediate download.