Data mining tools trawl for IC icebergs

Dassault Systèmes and IC Manage have independently developed software to track the progress of chip-design projects, using patterns found in log and tool-output files to flag up problems lying beneath the surface and determine how likely a project is to meet its schedule.

“I think this is the first true big-data application in EDA,” Dean Drako, IC Manage president and CEO, claimed. “We are using a big-data architecture for the database and we’re taking unstructured data, from log files that are mostly just thrown out, and looking for patterns.”

Michael Munsey, director of semiconductor strategy for Dassault’s Enovia group, said: “No-one’s favorite job is opening up Excel to tell your manager where you are. Instead, we can do big-data analytics. We call it predictive analytics. Not only do you have design data, you have project plans and information for manufacturing. You can start doing data mining for this predictive analysis. A lot of intelligence is buried in this data.

Image A project statistics view in IC Manage's Envision

“Using the analysis, we can mine data for specific roles. We can provide RTL functional, physical design and other dashboards. It is all very customizable and management can create multiple dashboards,” Munsey added.

Checking in, checking out

Drako said for IC Manage’s Envision software “a big piece of the data comes from the design-management system. We get the hierarchical data and the version data. We know what part of the design is being worked on. We look at the check-ins and the check-outs and analyze that data. Who’s got the data? For how long? Then we tie into that the tool-results data from DRC, LVS, simulation runs. You can get useful data not just from log files of the tools themselves but log files of license managers and job-queueing systems.

“Once you have all that you know what was run, when it was run, what it was run on. Was it any good? Did it fail? After a number of rounds of synthesis, what is the slack time. Or for a block near completion, how many DRC errors,” Drako added, pointing to the way that the software will pick up anomalies such as blocks that do not fit the normal profile. “This block has been marked as done but only one synthesis has been run. That seems weird. So we can see the progress in real time. Using all this data you you can see whether the project’s on track and will finish when it’s supposed to finish.”

Munsey said the data mining provides valuable long-term data: “If you have this DSP core that has been used in a number of design, you may find out these guys have done the best job of completing the job the quickest. You can make predictions about schedules using the data but you can also look at the whole team and resources. And how they manage themselves against project plans. You can see what teams are best at.”

Resource requirements

Drako added: “You can look at the data and find out ‘we could have bought that IP block, Maybe next time we should just buy it’. Another result of that analysis is resource allocation: when and where to use more resources a little better. You can see which blocks are in trouble. You have to sort those our or you will end up being behind by two months. You can visually and clearly what resources are being used on what.

“Engineers may have been working on this particular block for two weeks and the slack time hasn’t gone down. They’re banging their heads against the wall. Maybe they need help or you need to change the design. In other cases, a block may be not be as far along as it should be because they have been trying to fix other problem. Engineers think they can catch up and so don’t flag it. But using this approach you can easily see it’s behind where it should be.

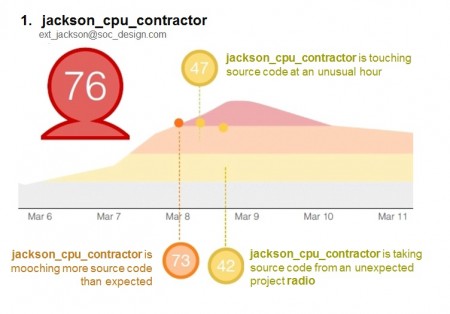

Image Tracking a contractor's suspicious behavior using Envision

“Then, after you do this a few times. You learn the characteristics of your design style. You can get pretty accurate predictions how long things are going to take. Using Envision, six months ahead of time, Xilinx with a couple of prior runs under their belts were able to predict tape-out on their next project to within a week,” Drako said, claiming that with the help of multipliers the results from projects can help cost and predict schedules on future designs.

“Teams can use the data to ask: ‘”We did a design at 20nm. Now dropping it down to 14nm, what’s the overhead of dropping it down?” Drako said.

Another use of Envision, Drako said, lies in design protection. “Once you’re analyzing all your data youcan look for aberrant behavior. Normally an engineer works only on his blocks. But oftentimes if someone is going to lift IP and leave, they start browsing into new areas or perform bulk downloads. You can detect that behavior and flag it. Maybe it’s legit, maybe not.

“There are six or seven kinds of behavior that indicate possible malicious intent. You can flag them and stop them. And establish some rules around them. We think thats going to be interesting to a lot of people.”