Silicon lifecycle solutions help you listen to your chip

New trends in semiconductors bring fresh challenges and innovative solutions. Next-generation SoCs are designed for electronic systems that require higher levels of reliability, safety, performance, and security. The end products have typically already been subject to product lifecycle management (PLM), a technique pioneered by Siemens. PLM helps to trace and manage the lifecycle of a product from inception through design, realization, deployment, and field service, all the way through to end-of-life activities such as final disposal. That same level of scrutiny is now being adopted for the ICs that power those electronic products. The practice is known as silicon lifecycle management. An overview is shown in Figure 1.

Figure 1. Silicon lifecycle solutions encompass design, realization, and utilization, addressing debug, test, yield management, safety and security, and in-field optimization (Siemens EDA)

Drivers and benefits of silicon lifecycle management

Progress in the semiconductor industry relies on process technology scaling, design scaling, and system-level scaling. Process technology scaling is the shrinking of circuitry. It leads to IC designs that are bigger in size and greater in complexity which are then built into devices that are ever more complex, pervasive, and mission-critical.

The challenges to staying competitive in the semiconductor markets of today and tomorrow span the entire IC lifecycle from concept to design, fabrication, and deployment. Silicon lifecycle solutions (SLS) are away of achieving all this that give unprecedented visibility into the life of your silicon.

So what does SLS look like? An SLS platform collects data from the chip and from the processes involved in its production. It mines potentially huge volumes of data, delivering actionable information when and where it is needed. SLS is the foundation of a holistic approach that allows semiconductor companies to improve existing processes. For example, advanced DFT techniques enhance IC quality, increase test efficiency, and enable diagnosis-driven yield analysis (DDYA). But SLS takes things further by using the on-chip hardware and DFT logic to monitor and asses circuit behavior and then collect data that feeds a fab-to-field optimization loop.

Embedded functional monitors are another key component of SLS. They acquire relevant data in a manageable form and then formulate and implement local responses where necessary. For example, the semiconductors used in the next generation of safety-critical devices deployed in cars must ensure reliability, safety, and security from cyber attacks. SLS is the framework through which an automotive SoC can be monitored and assessed throughout its entire service life.

Elements of silicon lifecycle management

SLS encompasses the traditional semiconductor value chain – design, manufacturing, test, and bring-up. It also reaches deep into the deployment phase of the device. It provides information that makes it easier for customers to design-in the device and bring up end products, enabling continuous in-field monitoring for preventive maintenance in the field, and ensuring devices remain performant after in-the-field upgrades. It feeds information forward from the device manufacturer to OEM customers and end-users and takes information back from the field for use in the semiconductor concept and production process.

Two fundamentals underpin realizing the full benefits of SLS:

- The semiconductor architect needs to include design augmentations that gather data from the chip and facilitate the rest of the process.

- SLS must be recognized as a multi-actor paradigm that draws together semiconductor IP providers, chip developers, fabrication facilities, OEMs, service companies, and database and analytics providers. Importantly, some of these roles can be performed by third parties outside the main company developing the product, notably fabrication.

At the front end of the process, the on-chip data sources include DFT logic, parametric monitors, and functional monitors. All the sensors, monitors, and DFT logic can produce huge amounts of data – enough to overwhelm even the best-designed analytics capability. A best-in-class monitoring infrastructure takes account of this by making monitors configurable at runtime to acquire only data of interest, by incorporating data compression technology, and by including fast external connectivity to move the data off-chip.

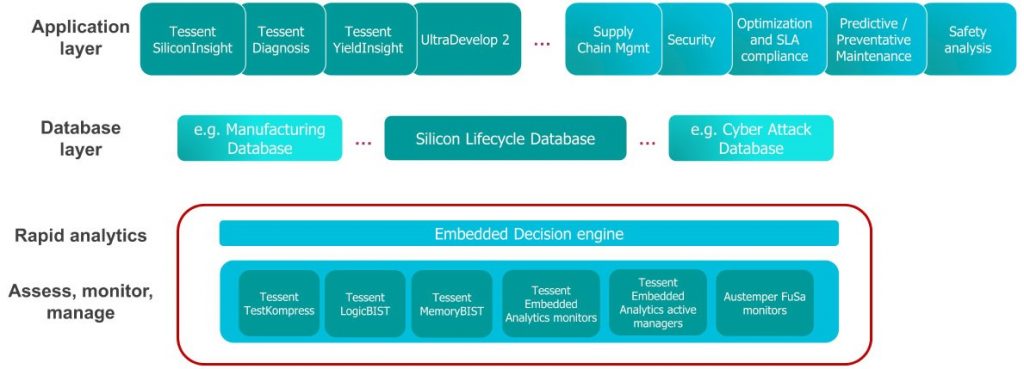

As an example of a complete SLS platform, the Siemens Digital Industries Software (Siemens EDA) portfolio of tools that span the entire semiconductor value chain is illustrated in figure 2.

This platform has four distinct layers:

Assess, monitor, and manage

This layer comprises the sensors and monitors that form the foundation of the SLS platform, gathering data about the system that can be used at various stages of the lifecycle. It includes the DFT logic that identifies structural defects and degradations. It also has functional monitors (embedded analytics) that observe the interactions between silicon subsystems and between the silicon and the embedded software. These allow designers to intelligently monitor, understand and control the activity of any on-chip structure – including custom logic, interconnects, and CPU cores. These monitors provide full visibility into the silicon system, as well as smart data filtering and real-time, wire-speed operation.

Rapid analytics

This layer is a low-latency response embedded decision engine that detects, understands, and responds to a threat in the minimum amount of time. In some end-use applications, a fast reaction time is critical – in particular where there are security, safety, and privacy concerns such as in transportation or data centers. For example, in a self-driving automotive application, the system might detect stuck pixels on the camera feed and it would then be down to the main CPU to decide what course of action to take.

Database layer

This layer comprises applications that gather and store the large amount of data generated by the on-chip monitoring IP at different stages of the lifecycle. This inevitably involves data from multiple vendors and sources – from stages such as design through manufacture, operation, and retirement. In recognition, open APIs, partnerships, federation capabilities, and participation in relevant standards organizations are critical factors for success.

Application layer

A host of applications can be enabled or enhanced by the use of data from silicon systems. Examples include applications for failure diagnosis, root-cause analysis, test bring-up, debug, silicon characterization, and system-wide debug in emulation and bring-up.

An SLS platform has many necessary elements. It will include functional, structural, and parametric monitoring. It will have analytics hardware and software (both on-chip and in the cloud). And its supplier will have made a commitment to open interfaces, partnerships, federation capabilities, and appropriate standards efforts.

With all of these in place, SLS addresses the emerging and pressing need to apply product lifecycle management principles to the semiconductor value chain. Bringing together the silicon lifecycle management ecosystem will enable a new phase of growth and development in semiconductors, and allow the industry to keep its place at the heart of innovation for the next generation of products and technology.

For more information, download this whitepaper: Tessent Silicon Lifecycle Solutions: Enabling the next step in IC test and monitoring.

Aileen Ryan is the senior director of strategy for Tessent Silicon Lifecycle Solutions, Siemens Digital Industries Software