May the Cloud be with you

In the Star Wars saga, a large force of wildly diverse, far flung interstellar species must come together to resist the inimical forces of the Empire. When you have a Rebel Alliance whose membership includes a human catfish, tittering crawfish, talking slugs, a squawking sasquatch, beeping blinking robots, and a parable-tongued troll prone to inverted syntax, all hailing from the farthest flung reaches of several galaxies…well, you better have a pretty good system for common communication and collaboration. “The Cloud, you need, Master Luke.”

While earthbound electronic systems design companies do not face such a collaboration challenge, they do face the product, process, and organizational complexities that come with cutting-edge designs, multi-domain flows, and globally dispersed teams.

The intense pressure to deliver next-generation designs on time and on budget compels companies to seek innovative, digitally transformative solutions that deliver the rewards of complexity and propel them to first time success.

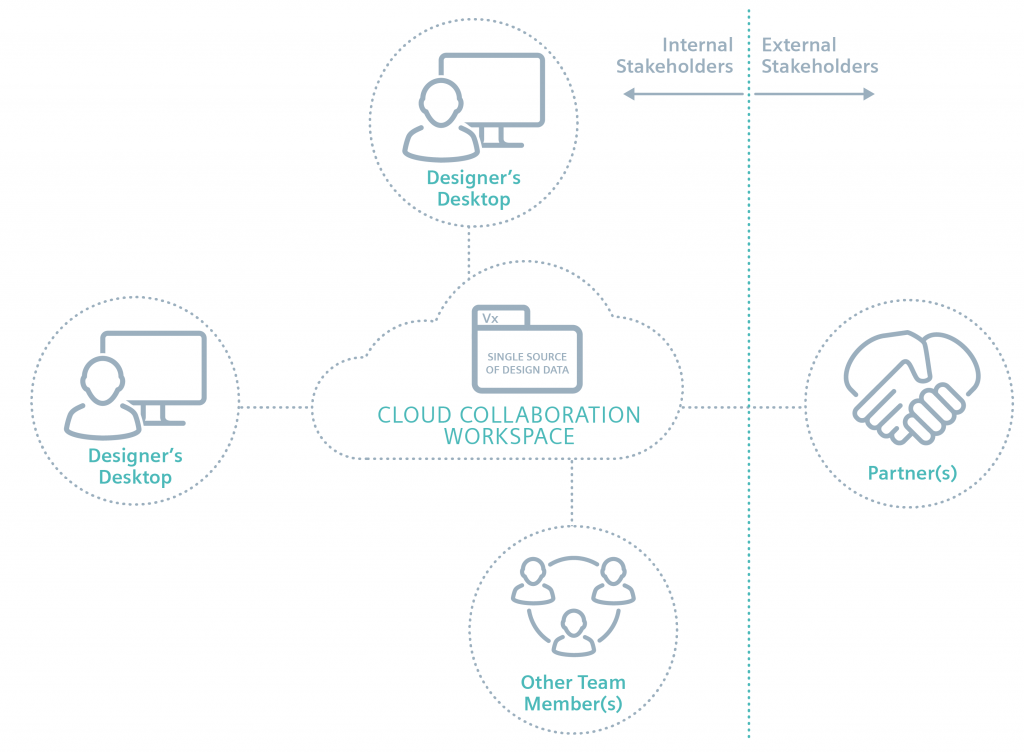

Given the complexities inherent in both next-generation products and the underlying components used, effective collaboration is fundamental to successfully navigating the product creation journey. This includes collaboration within the engineering and design organization, collaboration across organizational boundaries (including co-workers in procurement and support) and, as necessary, collaboration that extends to partners both on the frontend during ideation and on the backend during the NPI process. Teams that are better synchronized and aligned are far more likely to deliver a successful product to market on time and on budget.

The basis for improved collaboration is a single source of design data that contains schematics, simulations, PCB layouts, BOMs, manufacturing files, and so on. Teams have been sharing these files for decades; however, the traditional way of sharing information is ad hoc, disjointed, and multi-sourced, and therefore susceptible to persistent inefficiencies. These inefficiencies then accumulate throughout the product creation process in the form of time delays from process or human error, and lead to respins and negative impacts on development budgets, revenue, and gross margins.

Conversely, the cloud represents the perfect hub for organizing and managing design data. Anywhere, anytime, team members have access to the latest design revision. With the single source of design data in a designated cloud workspace, it is much easier for extended teams to collaborate, whether they work remotely or not.

Connecting teams over a cloud-based collaboration hub

So, what should you look for in a cloud-based hub for design, team, and partner collaboration?

Role-based user management

With potentially many individuals connecting to the collaboration workspace, controls need to be available to protect design IP from a mistaken use case. Said a different way, not all collaborators may be equal. For example, although a procurement person may have an engineering degree, you may not want them to have privileges allowing them to edit the PCB design posted in the collaboration workspace. And an owner/author of multiple designs may want to share separate, independent designs with different sets of collaborators. This is why role-based access control is a crucial capability for completely safeguarding secure access to design data. The owner of a design can invite any number of individuals as collaborators to a given project and assign each individual a role. For example, some may be assigned an ‘edit’ role, others may be ‘view only’.

More work, more joules

Simple project data management is a fundamental expectation for any collaboration workspace. Design authors publish the latest design data to the cloud and make it accessible to other stakeholders on the team, both internal and external. On its own, this baseline capability offers tremendous value by reducing the common inefficiencies and process or human error that delay projects (e.g., when the PCB layout gets done on the wrong version of the design, or the latest FPGA section of the design is missing from the network share drive for the project—and design review is in one hour).

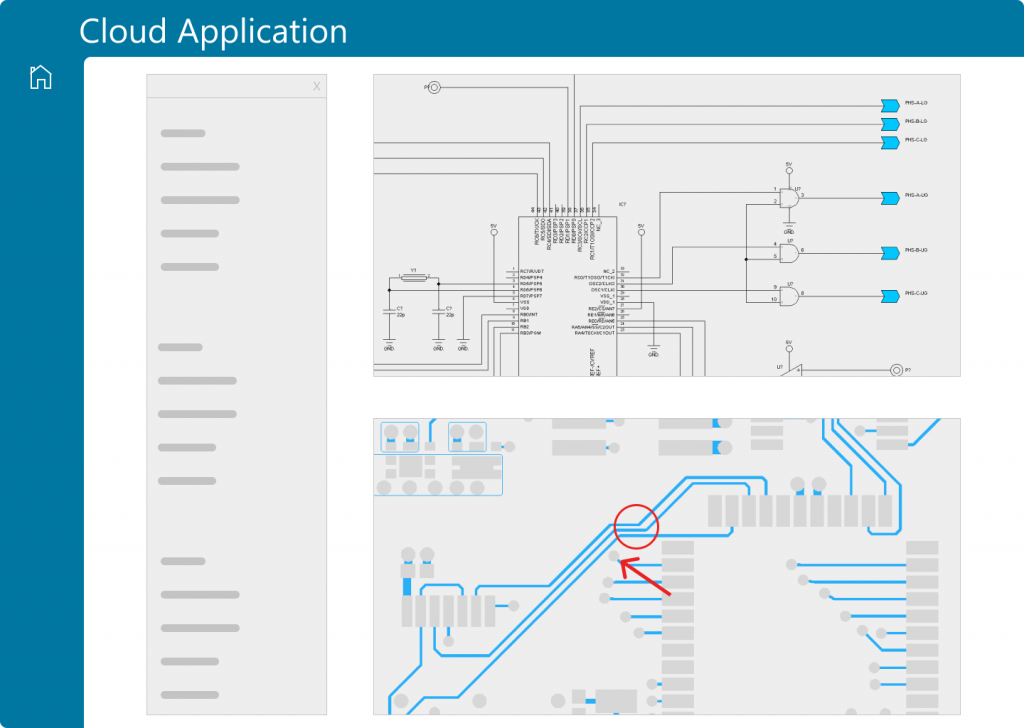

The more work that can be done on a single source of design data, the more potential energy, in the form of team productivity, can be derived from the collaboration workspace.

Consider this example: Adding visualization and markup capabilities to the collaboration workspace makes the design review process much more productive. The broader design team can easily view the schematic and 2D layout simultaneously with the 3D layout within the collaboration hub. The ability to cross-probe helps anyone on the collaboration team identify and hone-in on sections of the design under review. The ability to add annotations and markups further documents the collective feedback, thus archiving design review guidance and next steps.

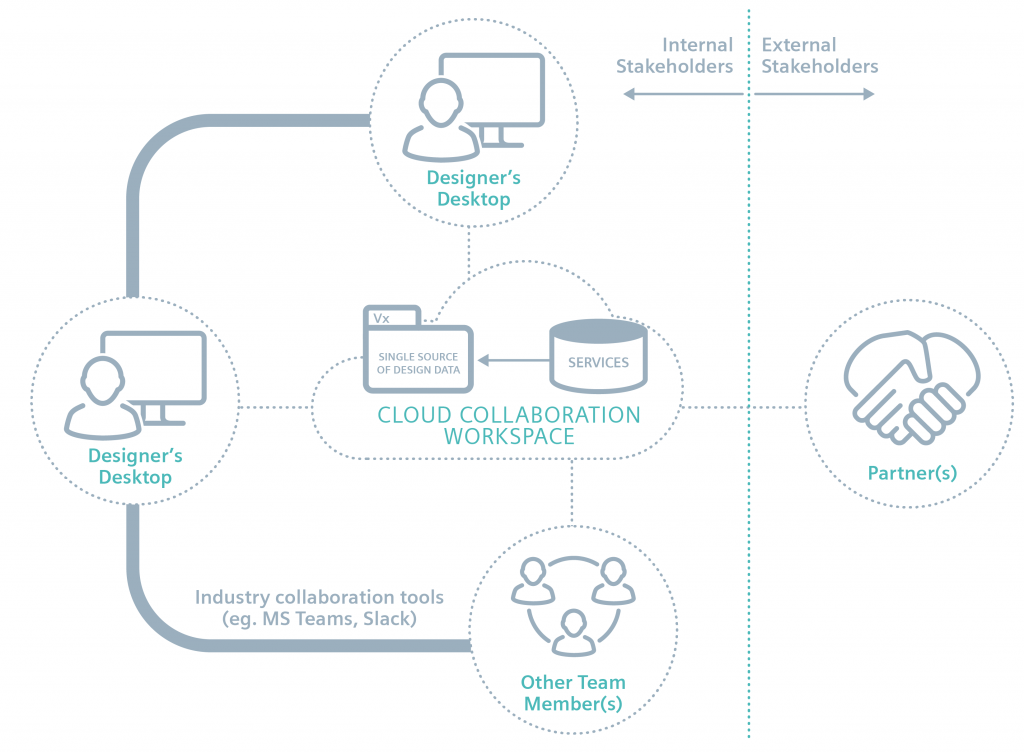

Consistent and inclusive communication among team members is crucial to keeping everyone on the same page. Doing this effectively though takes time and you have to remember to include everyone. Have you ever forgotten to include someone on an email thread or meeting invitation? Happens all the time. This is why most companies have invested in productivity tools like Microsoft Teams or Slack to keep organizations synchronized, especially when working remotely.

An effective collaboration workspace for electronics design should seamlessly integrate with these popular tools to take full advantage of all modes of team communication. For example, when Jennifer uploads a new design revision to the collaboration workspace, email alerts should be sent to the team participants listed as collaborators on the project. Likewise, alerts should also automatically be sent to the Teams or Slack channels inclusive of the same list of collaborators on that project.

Collaboration workspaces are indispensable for all the reasons stated above, yet the entire team can benefit from other important utilities if the collaboration hub supports additional value-added services. These are services that allow more work to be done on the single source of design data without ever leaving the collaboration workspace. These services are meant to complement the connected desktop environment by adding productivity elements. For example, the ability to manage a shared library across the team within the collaboration workspace keeps the team focused on designing great products rather than tracking down needed components.

In addition, the following services build confidence (without risk) in the underlying design’s readiness for successful production release:

- BOM optimization: cost analysis and assessment of BOM risk

- DRC: running a design rule checker on the design gives confidence in electrical integrity

- Automated schematic integrity analysis: eliminates schematic design errors not visible during a manual check

- DFM: bringing forward manufacturing knowledge into the design domain highlights errors before they become problems

Figure 3. Additional value-added services allow more work to be done on the single source of data without leaving the collaboration workspace (Siemens)

No matter the flow, a collaboration layer that connects teams in a common productivity environment based on a single source of design data is critical. Together with the EDA Xpedition Enterprise solution from Siemens EDA, a part of Siemens Digital Industries Software, the cloud offers a new transformative option for teams wanting a hub for collaboration that enhances the power of the on-premises desktop environment.

Expectations for design teams to deliver tomorrow’s products today demand collaboration tools that go beyond makeshift or ad hoc approaches by delivering solutions geared to the challenges extended teams face. A collaboration hub that connects heterogeneous teams so that they can collectively innovate and deliver successful products to market on time and on budget is the key to winning the battle against the competition, design flows, and design inefficiencies. And by making such a collaboration solution an integral element in a fully integrated ecosystem solution, engineering teams and their allies will accelerate their electronics system design and, perhaps, save the universe.

May the Cloud be with you!

Further reading

To learn much more about our continuum of cloud-enabled solutions that unlock the full potential of your company’s digital transformation, please refer to these two whitepapers from Siemens EDA: Lost in the Cloud? Siemens Shows the Way and Tacking to Win: Connecting Teams with a Collaboration Hub in the Cloud

Matthew Walsh is a Product Marketing Manager in the Electronic Board Systems division of Siemens Digital Industries Software, responsible for all cloud solutions. He has more than 25 years of experience in semiconductor and electronics marketing, sales, and application engineering. He earned his BSEE at the University of Massachusetts. Matt is an avid skier and science fiction geek.

Matthew Walsh is a Product Marketing Manager in the Electronic Board Systems division of Siemens Digital Industries Software, responsible for all cloud solutions. He has more than 25 years of experience in semiconductor and electronics marketing, sales, and application engineering. He earned his BSEE at the University of Massachusetts. Matt is an avid skier and science fiction geek.