Control test point counts for ISO 26262

The ISO 26262 standard for automotive functional safety sets a high bar for test – specifically a target of 90% stuck-at coverage for in-system test.

Achieving this to satisfy both ATPG pattern counts for manufacturing and LBIST quality for logic has led to a massive increase in the number of test points applied to automotive designs.

One of the major inefficiencies is that the embedded deterministic test (EDT) circuitry required for ATPG and the LBIST test points have until now needed to be set through a two-step process, one pass for each type.

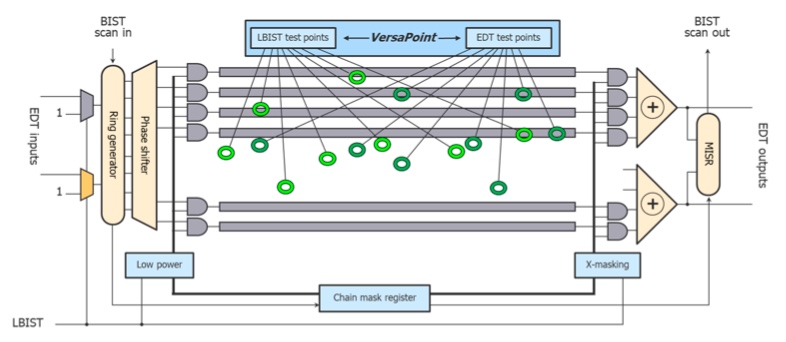

A new technology from Mentor, VersaPoint, aims to make the process more efficient by setting LBIST and EDT test points concurrently (Figure 1). Not only does this simplify the test flow but, according to a new white paper from the company, it also improves coverage.

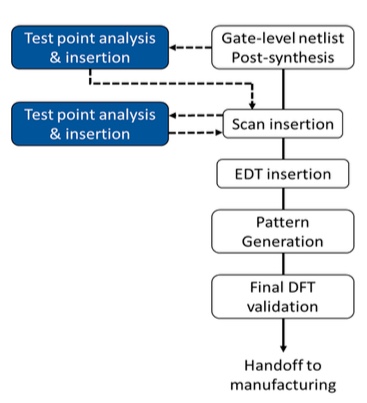

“Improving in-system test with Tessent VersaPoint Technology” describes both the new methodology (Figure 2) and also implementation data which shows VersaPoint can “add up to 5% LBIST test coverage or allow designs to achieve 90% test coveage with up to 10x fewer LBIST patterns”.

VersaPoint is now being incorporated in Tessent ScanPro and Tessent LogicBIST products within Mentor’s test software family.