Combining 1D and 3D CFD simulation for piping systems

There are various ways in which computational fluid dynamics (CFD) can be used to simulate complex piping systems. The challenge has been in combining 1D and 3D software simulations.

The two dimension levels meet different requirements. 1D CFD (also known as ‘thermo-fluid simulation’) addresses the thermal and hydrodynamic properties of a system. 3D CFD considers the interaction of the gases and liquids likely to be introduced into that system.

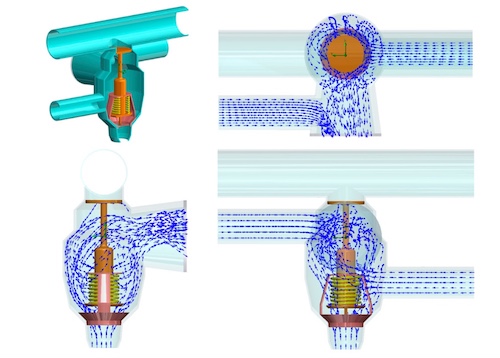

A new Mentor Graphics white paper describes how you can unite those types of analysis in a single workflow. As well as providing an overview of the technologies and tools involved, it describes a case study showing the methodology used for the characterization of a four-arm thermostat and the engine block/cylinder head in an automotive cooling application.

The example servers to illustrate the value of integrated 3D-to-1D simulation for similar markets such as mil/aero, oil, gas, power and energy.

Inside a 3D-to-1D CFD flow

The Mentor tools used for such CFD simulations are FloEFD for 3D CFD and FloMASTER for 1D CFD.

“[Using FloEFD], the highly 3D interacting nature of the flow can be resolved, without having to resort to assumptions or text-book relationships. A simulation-based characterization workflow enables FloEFD to be used to characterize complex geometries for subsequent use within a FloMASTER simulation,” writes the paper’s author, Dr Robin Bornoff of Mentor’s Mechanical Analysis Division.

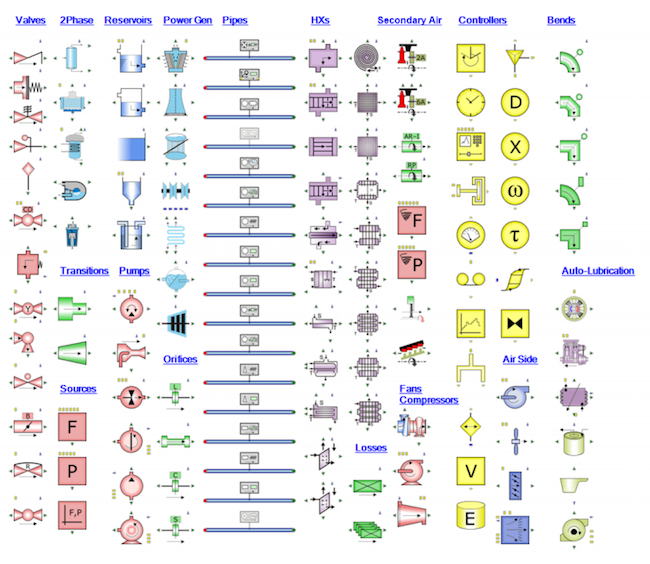

An advantage of FloMASTER is that it controls the large data volume required to run the 1D simulation because it includes a catalog of component descriptions suitable to almost all projects.

FloEFD is compatible with leading MCAD systems, including Creo, CATIA V5, Siemens NX, Solid Edge and SolidWorks. This allows the analysis to be undertaken earlier in a design flow.

‘Simulation-based characterization: A 3D-to-1D system level thermo-fluid CFD workflow’ can be downloaded at this link.